YOUR

3D POWDERHOUSE

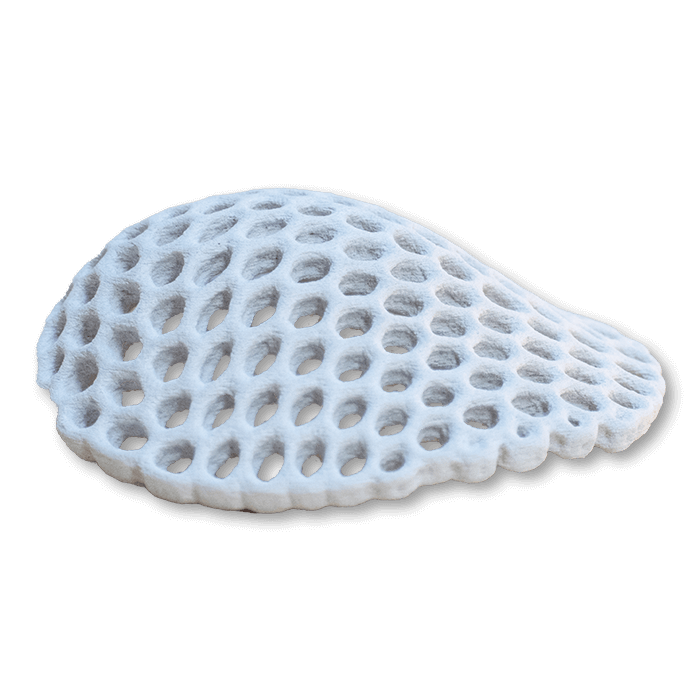

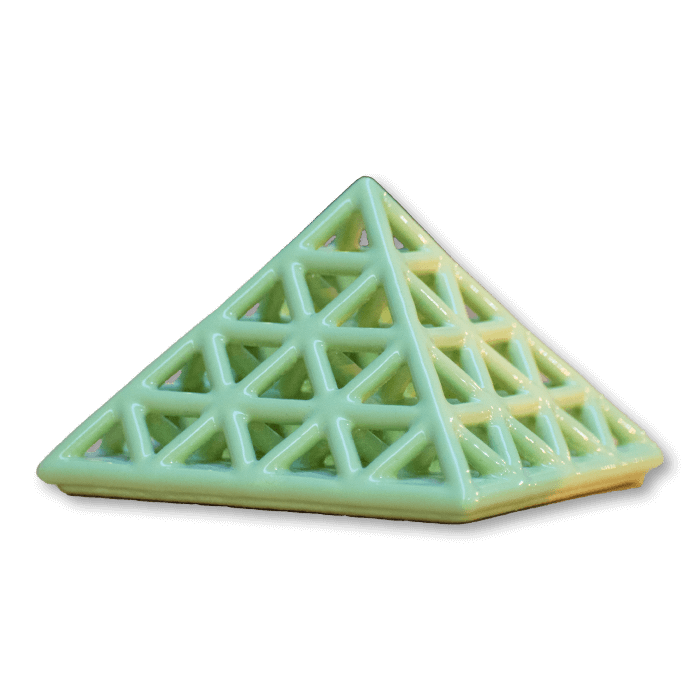

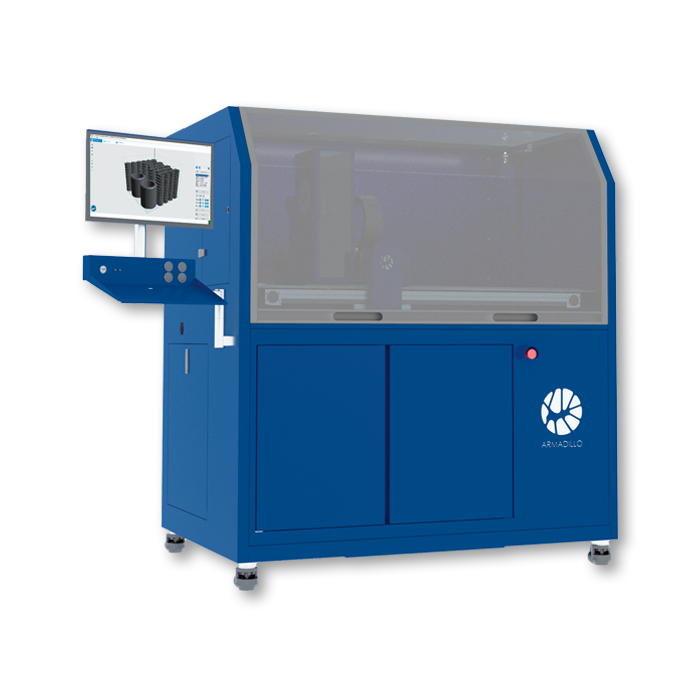

We build powder-based 3D printers that enable the unimaginable, produce the remarkable and shape the impossible. Our accessible ecosystem allows you to create accurate, complex parts with novel material properties, unprecedented scalability, and waste upcycling options – all in a single platform.