Product Design

Sustainable product design includes using natural (waste) materials to create value. Armadillo Green makes it possible to 3D print unique wooden products from sawdust waste. We do not add any harmful chemicals in the production process - with zero residual waste.

Armadillo Green

Armadillo Green was designed to advance the use of natural and entirely safe materials without any harmful compounds in additive manufacturing. This includes printing bio-based materials with our environmentally friendly and food-safe Bio Binder.

Print your own materials

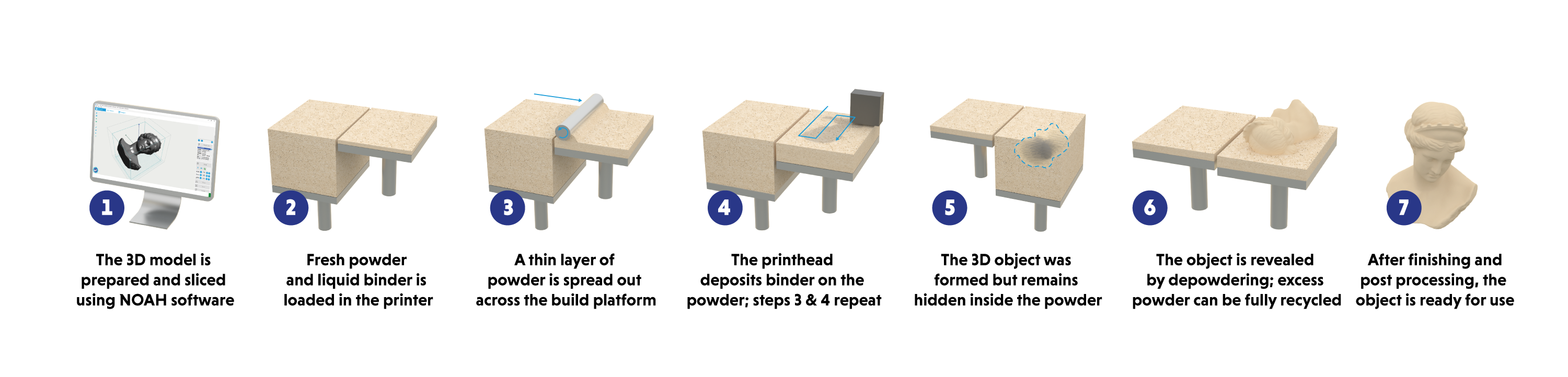

Our experts are ready to enable you to use your own powder-based material for printing. We can either test your powders with existing binders, or even create unique combinations with custom binders. We strive to deliver the material you are looking for.

Publications

Learn more about the process of 3D printing materials like Silicon Carbide in our Publication Library. We aim to share our knowledge in order to inspire others and together further advance the possibilities of sustainable production using our technology.