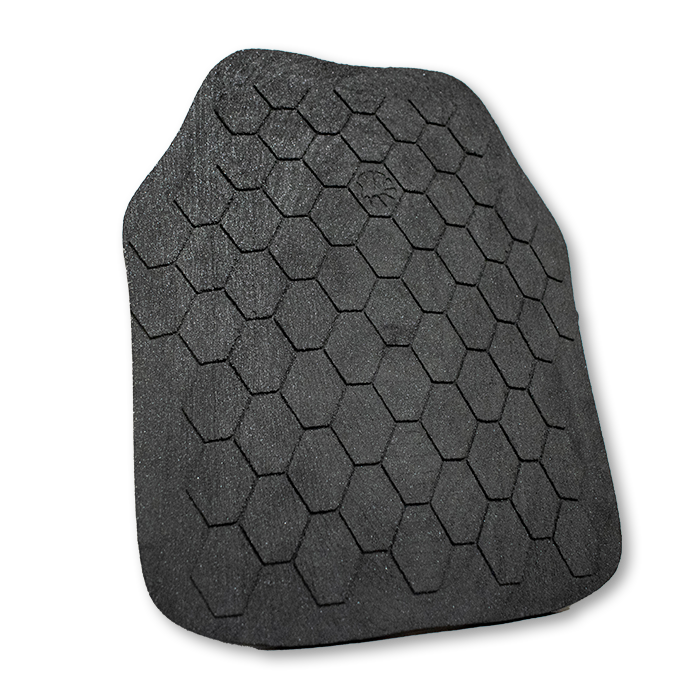

CONCR3DE Silicon Carbide

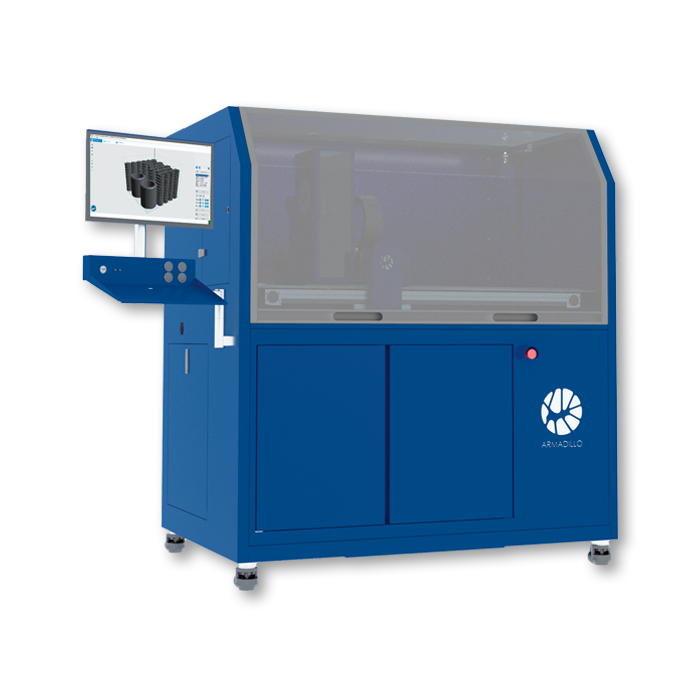

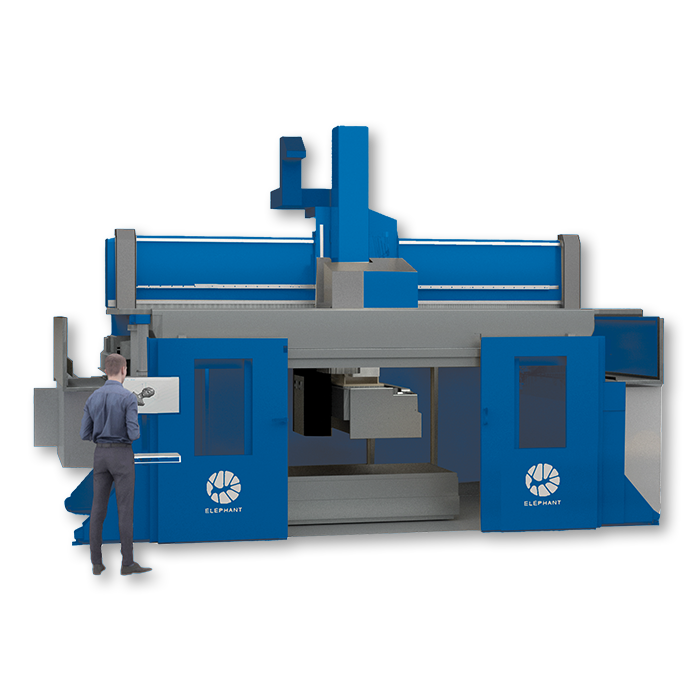

The CONCR3DE platform enables 3D printing of Silicon Carbide for Silicon Infiltration (SiSiC), achieving high density and precision at both lab and industrial scale.

|

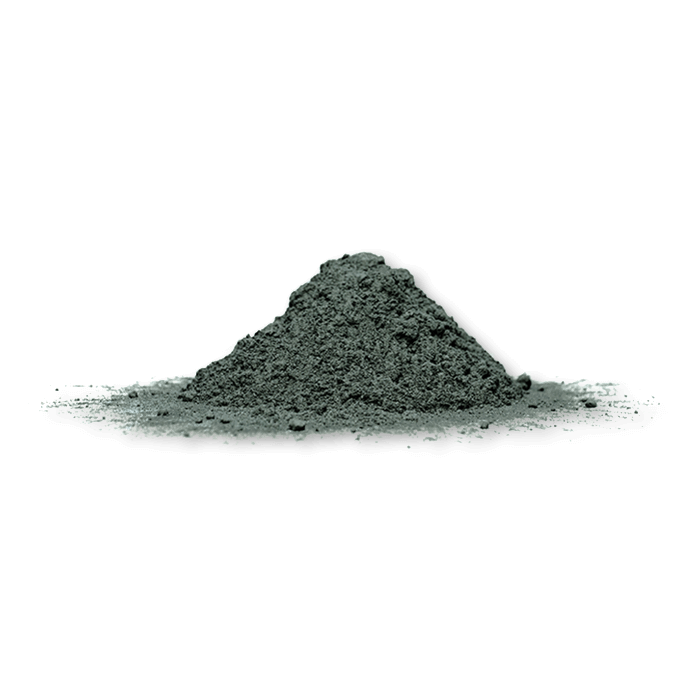

Powders PC1001 SiC Carbon Powder Customer SiC Powder |

Binders BC1001 Cer Binder (Aqueous) BM1001 M-Binder (Solvent) BF1002 Phenol Binder (Solvent ) |

|