Alumina

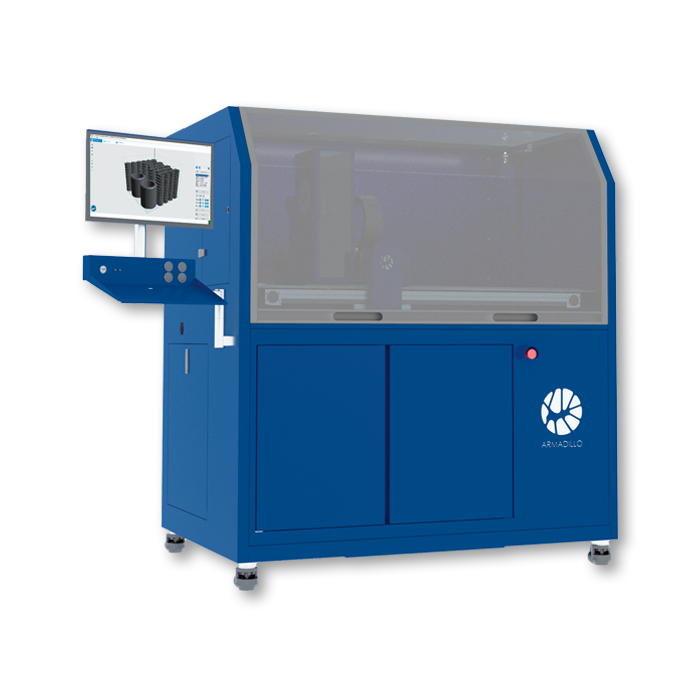

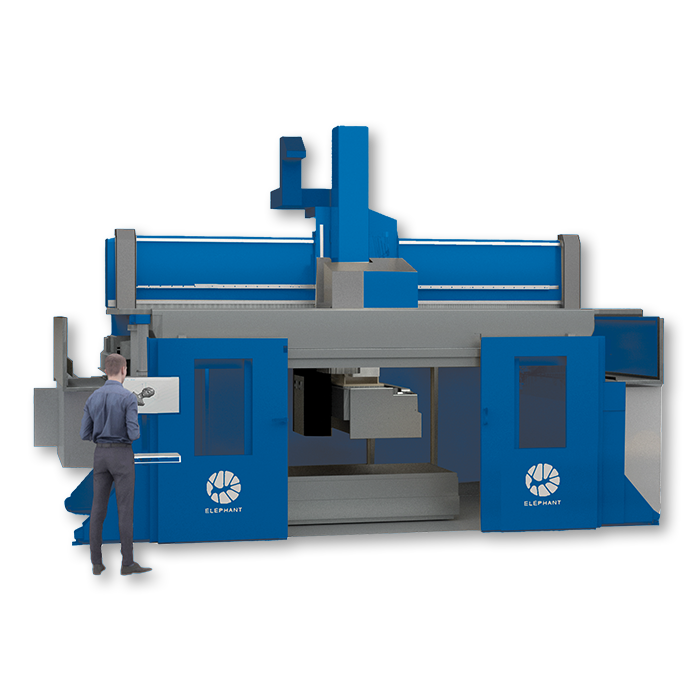

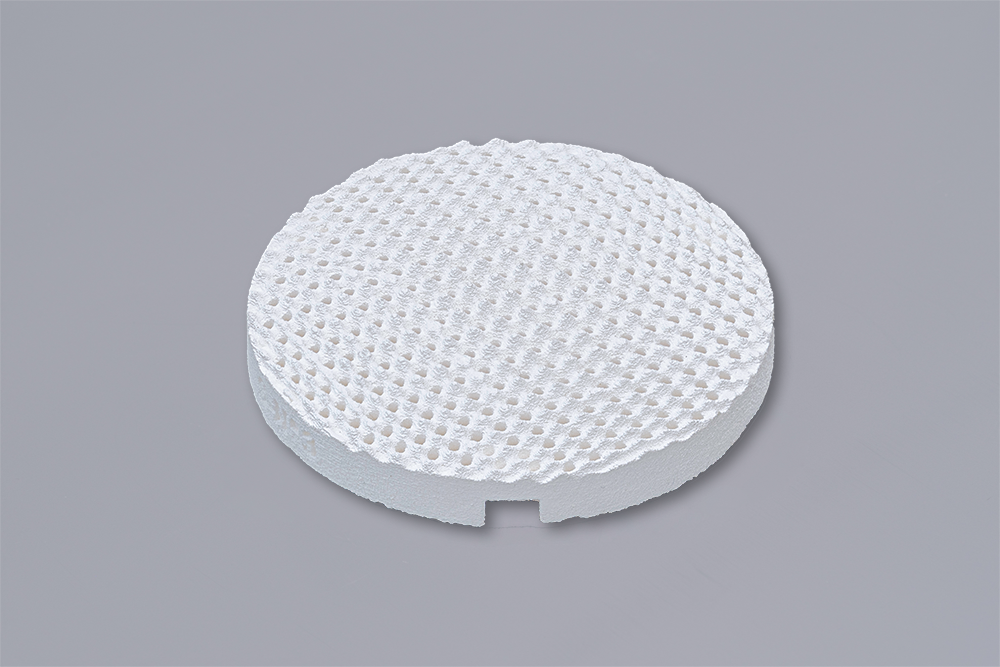

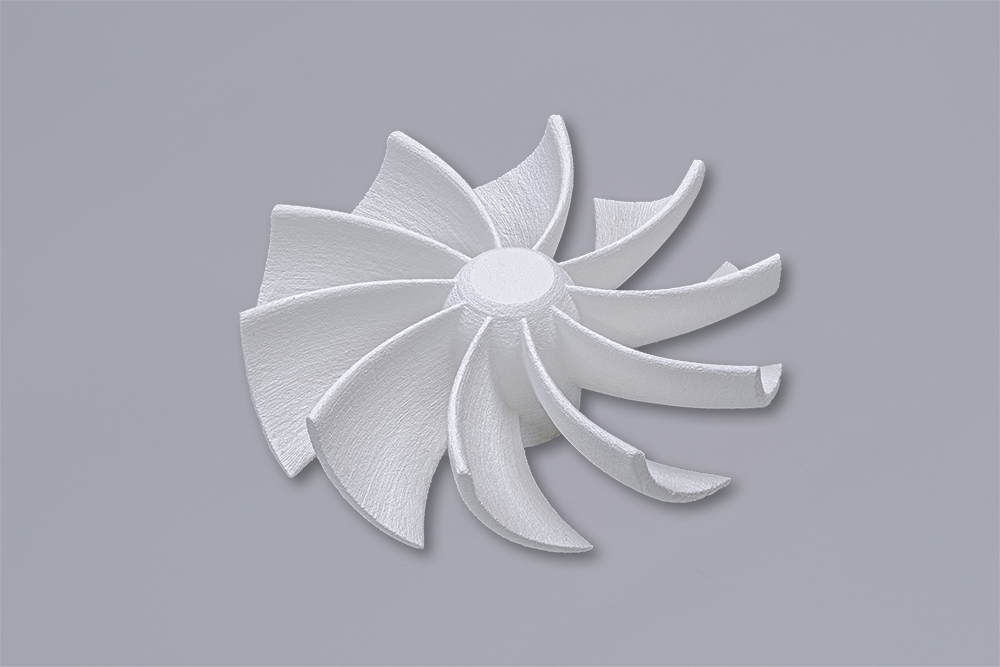

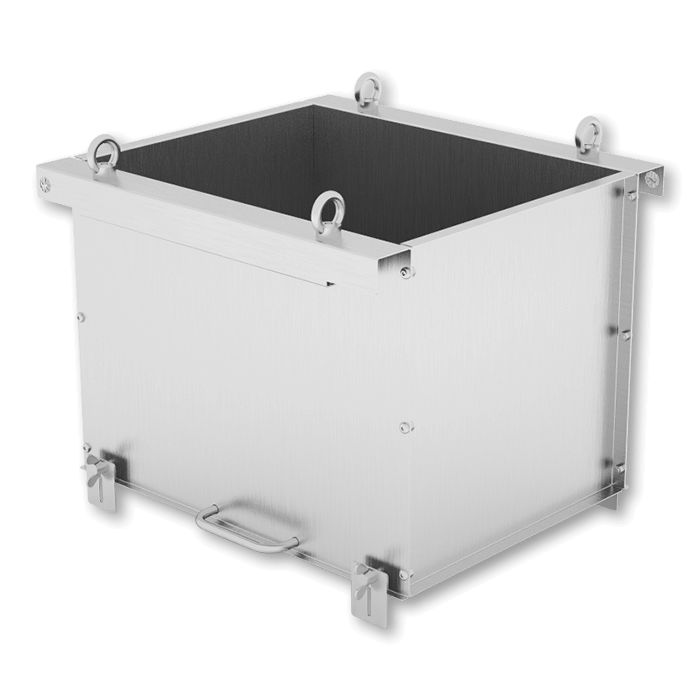

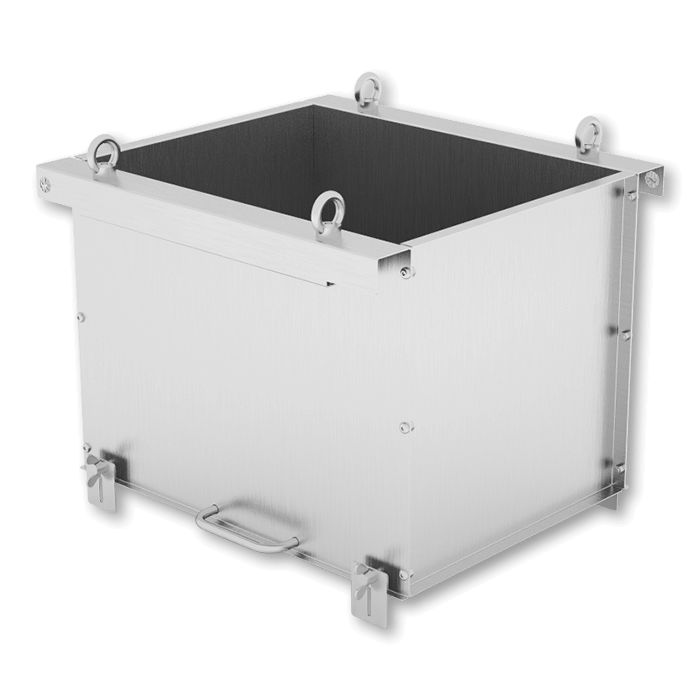

The CONCR3DE platform allows companies and research facilities to 3D print large and highly complex Alumina parts of various purity and with a range of achievable densities.

|

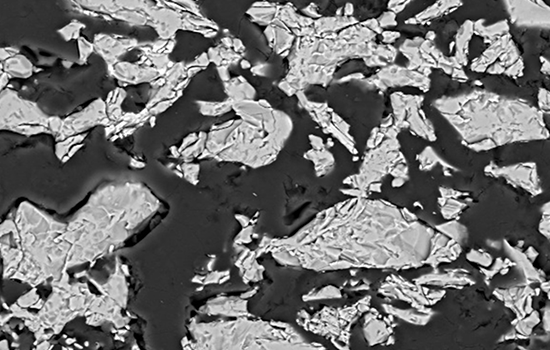

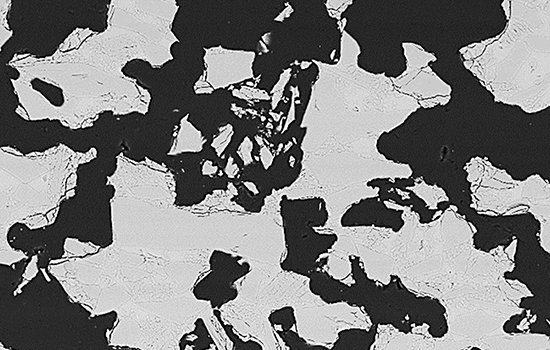

Powders PC1002 Alu92 Powder PC1003 Alu96 Powder PC1004 Alu99 Powder PC1005 Alu80 Powder |

Binders BC1002 Alox Binder (Aqueous, Particle-Filled) BC1001 Cer Binder (Aqueous) |

|