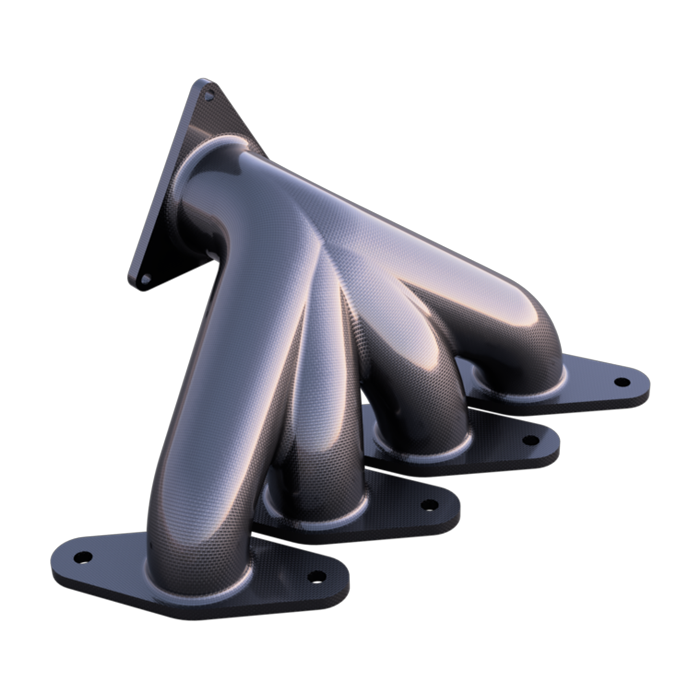

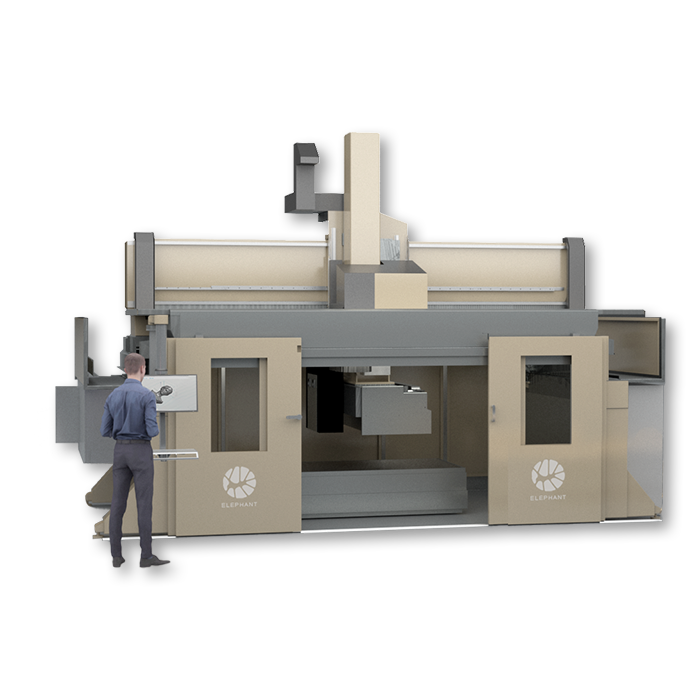

Washout

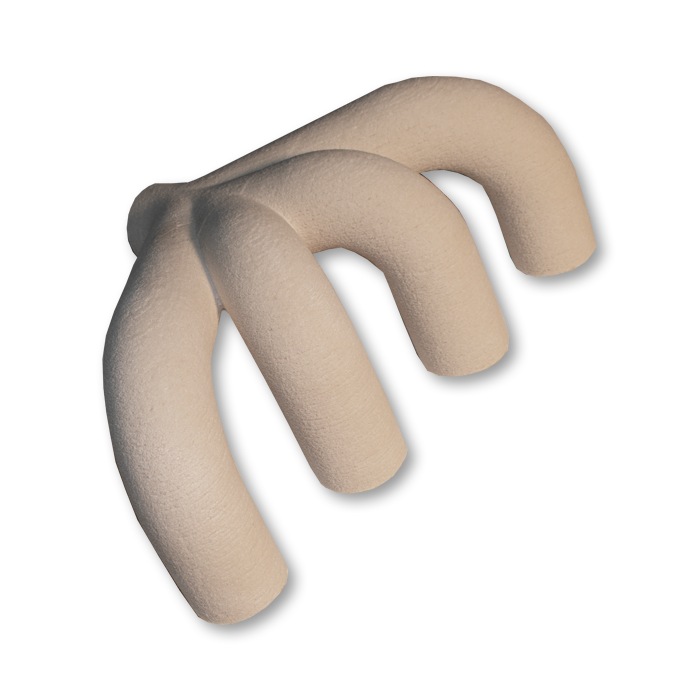

CONCR3DE enables to print advanced Washout materials, engineered for the fabrication of intricate composite tooling, from rapid prototyping and low-volume production to high-throughput industrial-scale manufacturing.

|

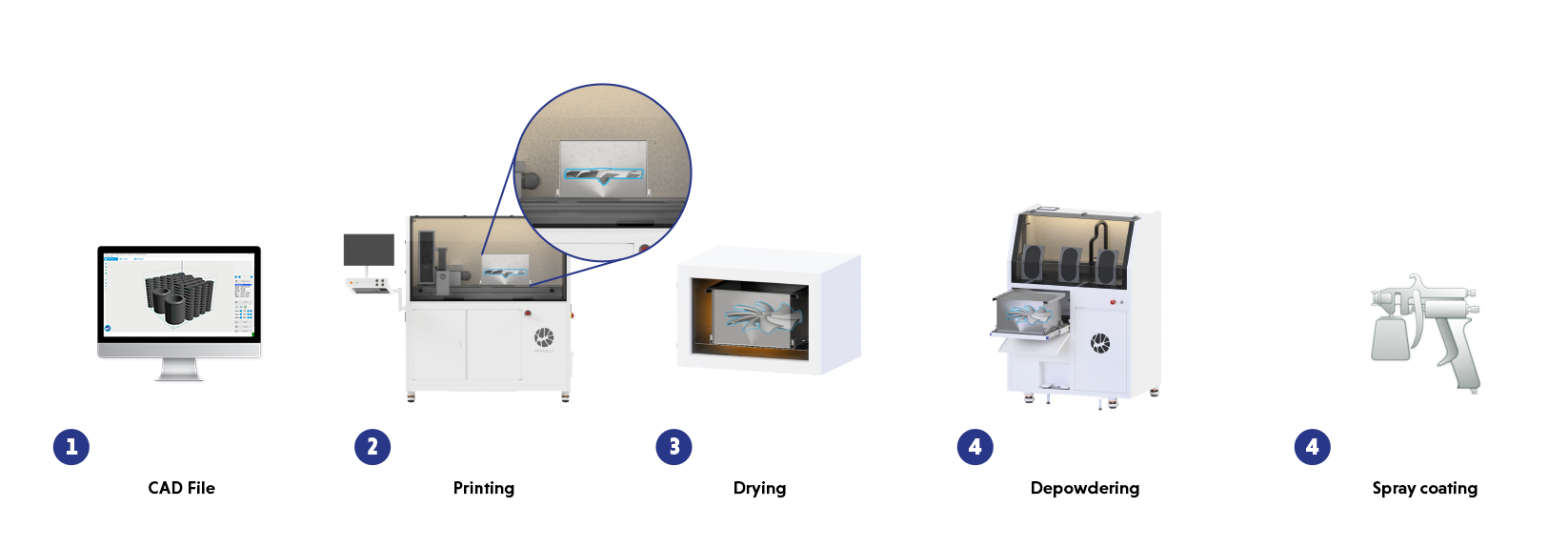

Powders PS1004 Gypsum Powder PS1005 Sand Powder PS1007 Cer Powder |

Binders BS1001 Mineral Binder (Aqueous) BS1002 Sol Binder (Aqueous) BS1003 Sol-C Binder (Aqueous) |

Other SS1002 Washout Coating (Optional) |