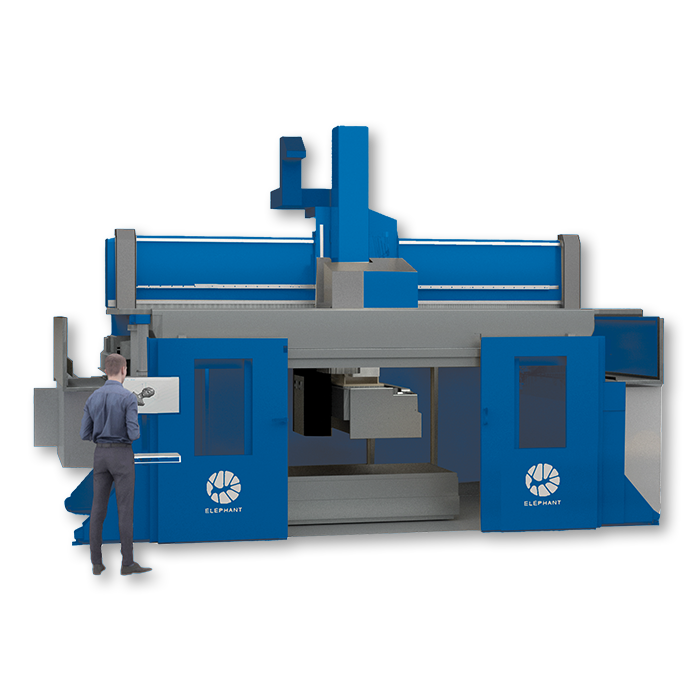

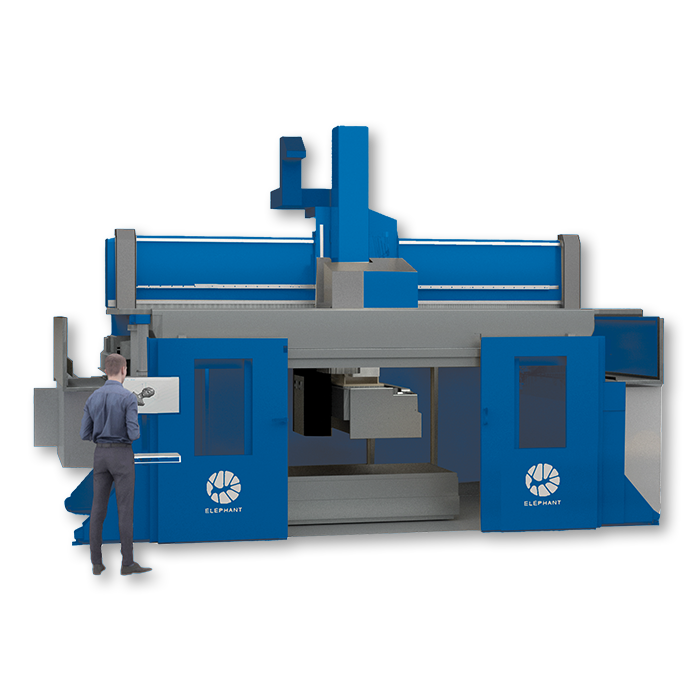

Elephant Blue

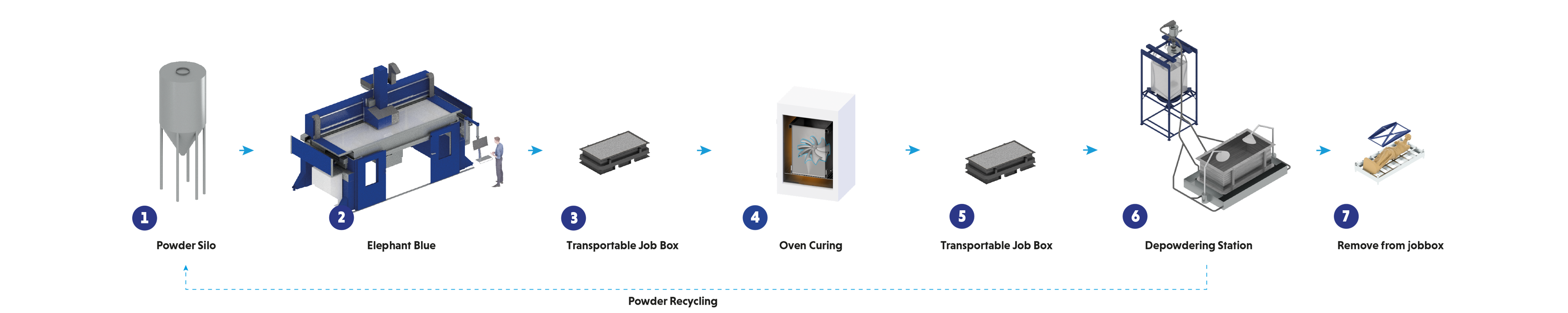

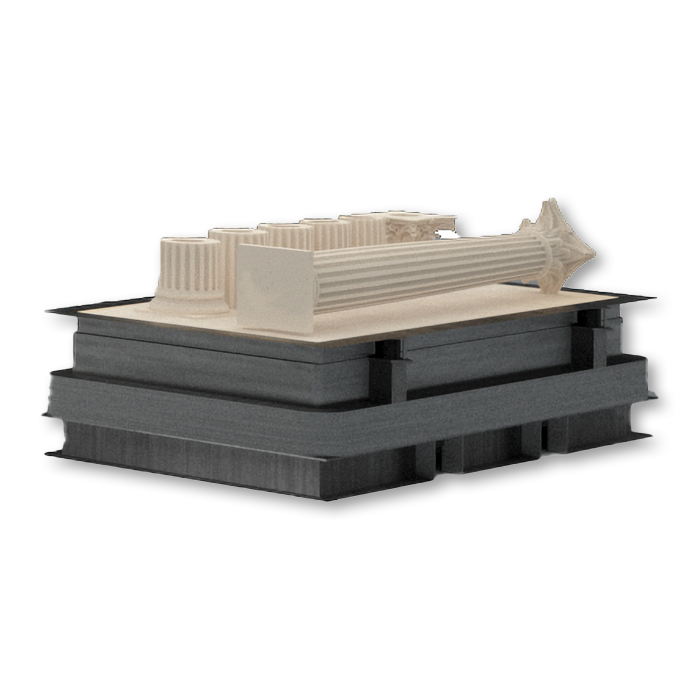

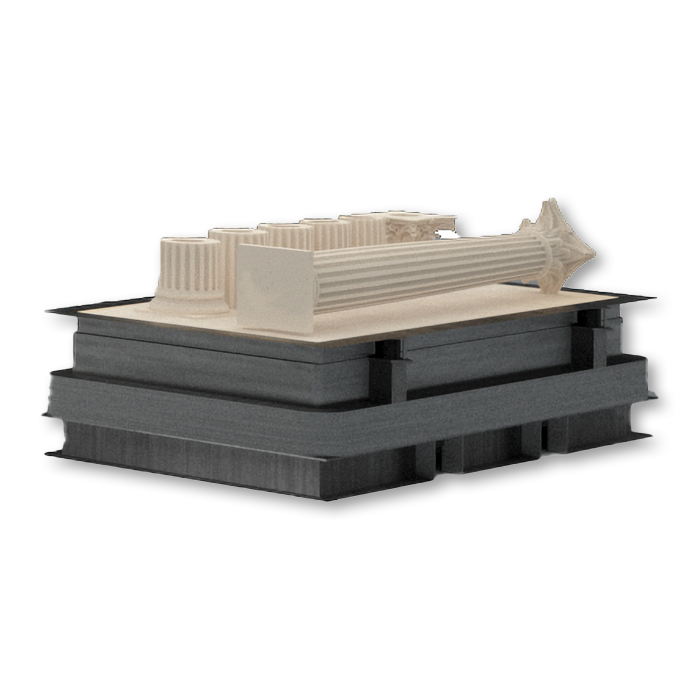

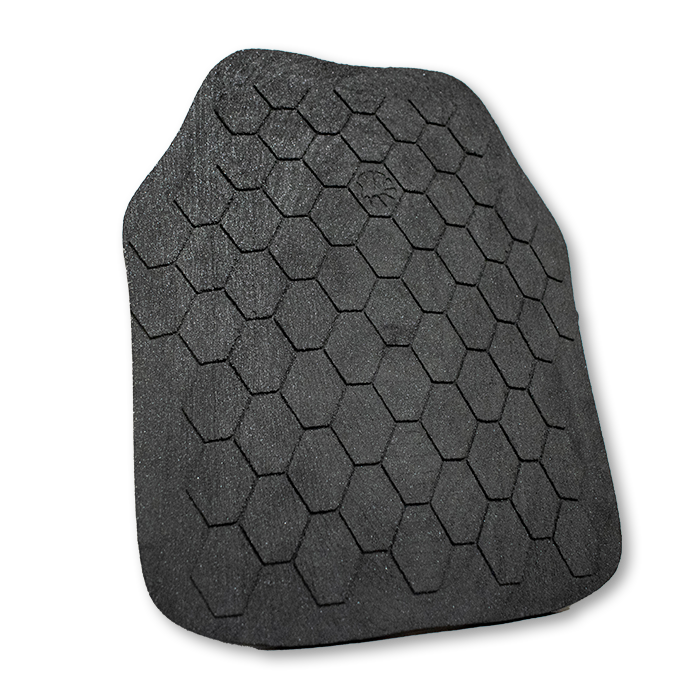

This large-scale 3D printer was designed for the industrial production of complex shapes in Silicon Carbide (SiSiC) and other ceramics.

| Elephant Blue | |

| Print box dimensions (X, Y, Z) | 1.000 x 2.000 x 1.000 mm |

| Capacity | 2.000 liters/day |

| Printhead precision | 400 DPI |

| Layer height | 150 - 300 µm |

| Powder compatibility | Optimized for PC1001 SiC Powder |

| Binder compatibility | BC, BM & BF range binders |

| Connectivity | Ethernet |

| Maximum power requirements | 2 x 400 V |

| Dimensions | 2.800 x 6.500 x 4.500 mm |

| Software | NOAH (included) |