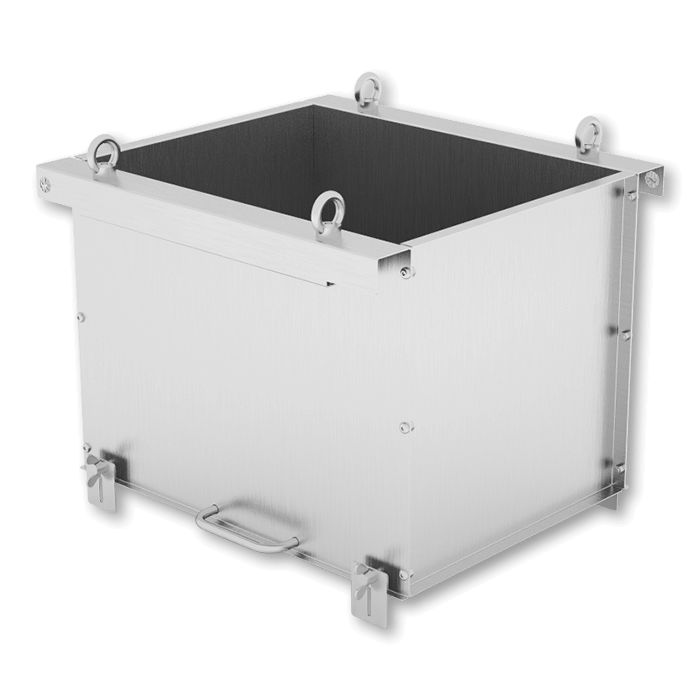

Construction & Design

CONCR3DE combines the benefits of additive manufacturing with stone and concrete materials to easily create complex forms, even in small series or as one-offs - with unprecedented scalability. Fast, cost-efficient, and of the highest quality.

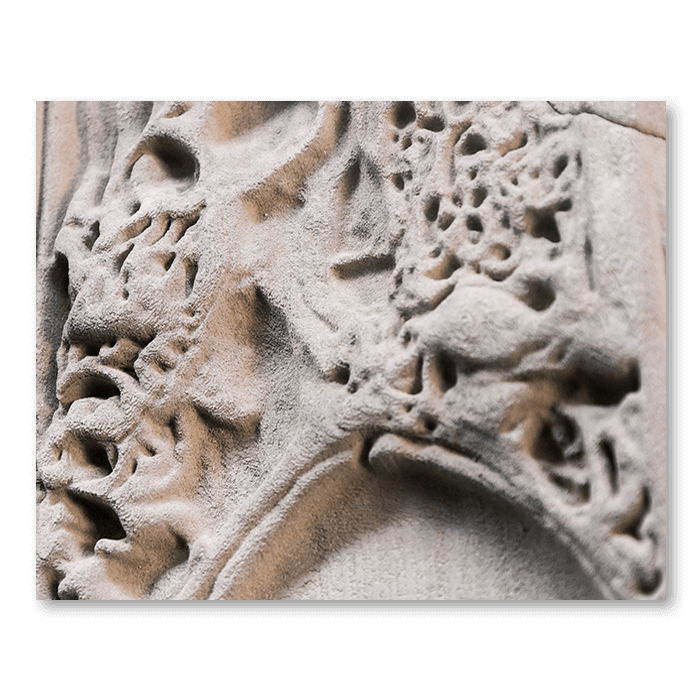

Stone & Minerals

CONCR3DE was founded on our desire to upcycle stone waste powders and create sustainable, inorganic, and functional 3D printing materials. We offer the specific binders to match and can customize materials and processes, as well as support research.

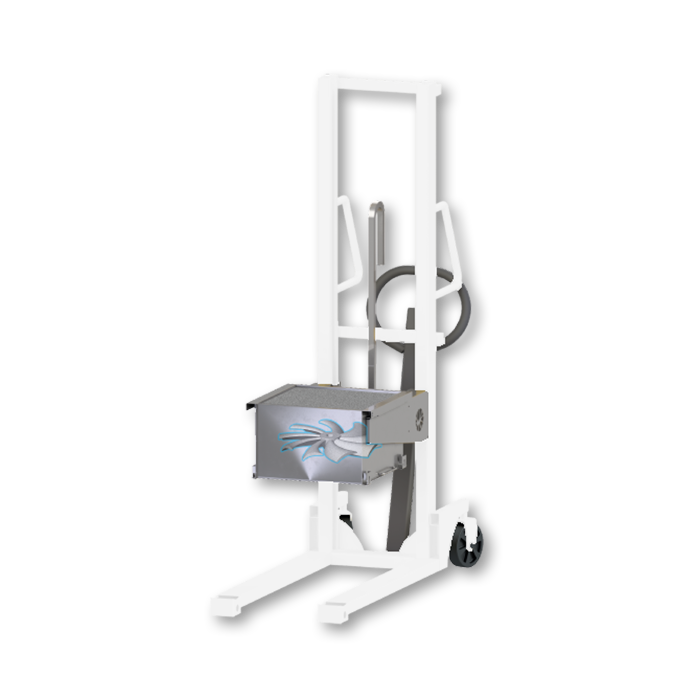

Technology

Binder jetting 3D printing is based on two key elements: a powder and a binder. The powder can be a concrete, metal, ceramic, or other material you want to bond in powder form. The binder is a liquid, which acts as an adhesive between powder layers.

Publications

Learn more about the process of 3D printing materials like Silicon Carbide in our Publication Library. We aim to share our knowledge in order to inspire others and together further advance the possibilities of sustainable production using our technology.