Development Services

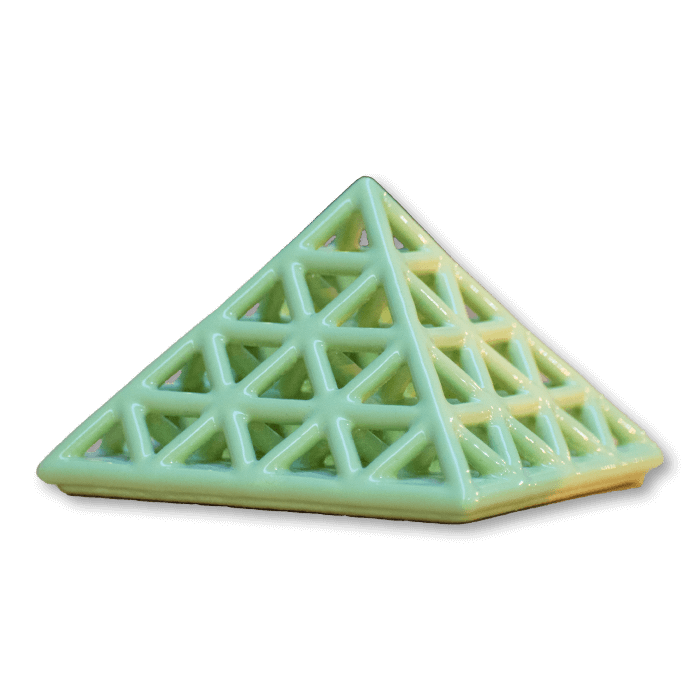

CONCR3DE offers Service Level Agreements as well as range of both Technical and Operational Services as well as Maintenance and Spare Part options to customers using our printers. Through years of experience and testing hundreds of materials, we are experts in getting your material printable and advising on post processing steps. Are you interested in exploring novel geometries, using your powder waste stream as 3D printing input, or developing a new application? Get in touch with our material experts and we can help you out.