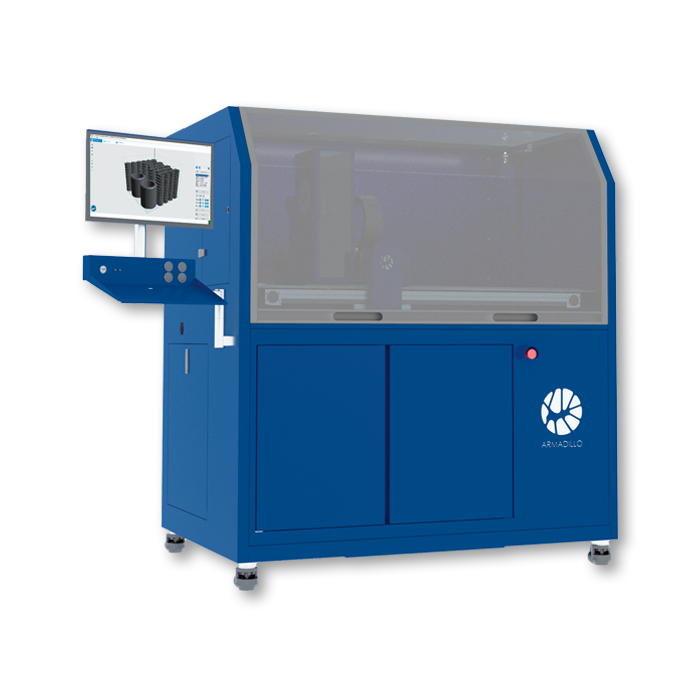

Armadillo Blue (XL)

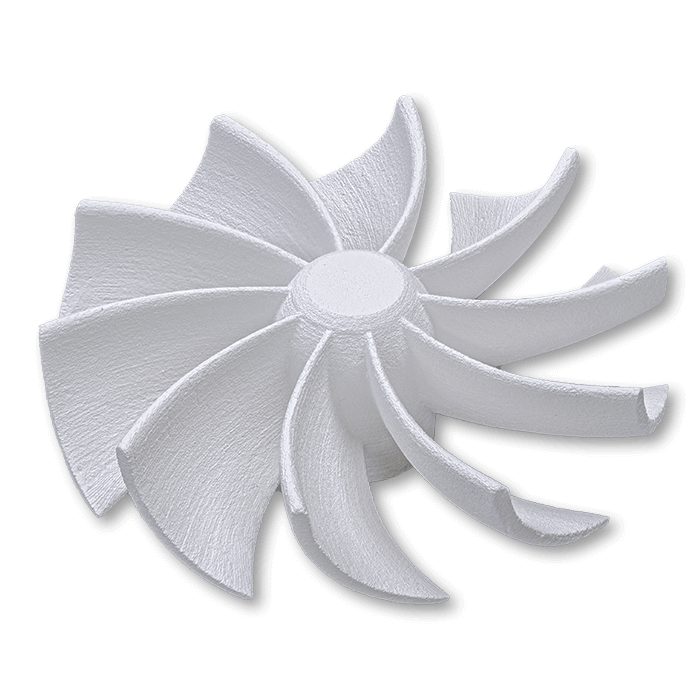

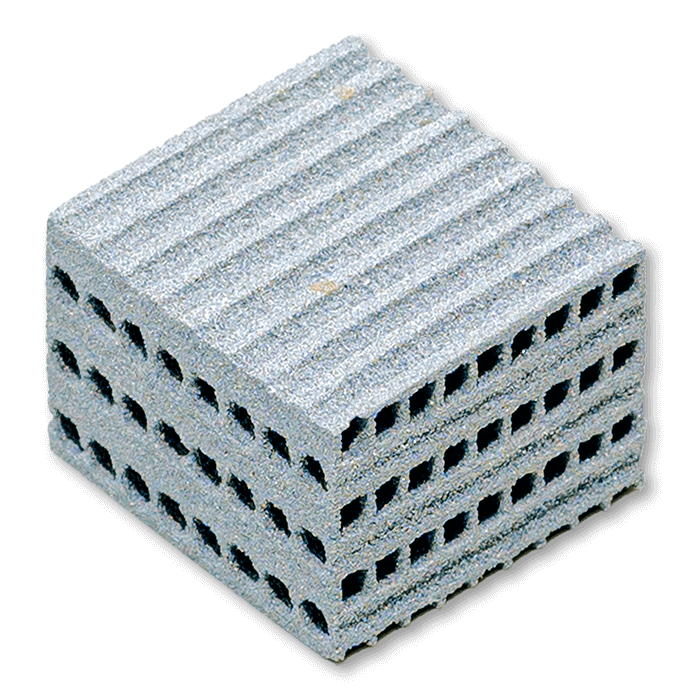

This binder jetting 3D printer comes fully featured with all applicable add-ons to print ceramics and metals. It includes an integrated control station running our NOAH software on optimized hardware, as well as our Infrared Heater and Depowdering Box for convenient handling after print. The XL version doubles the daily production volume.

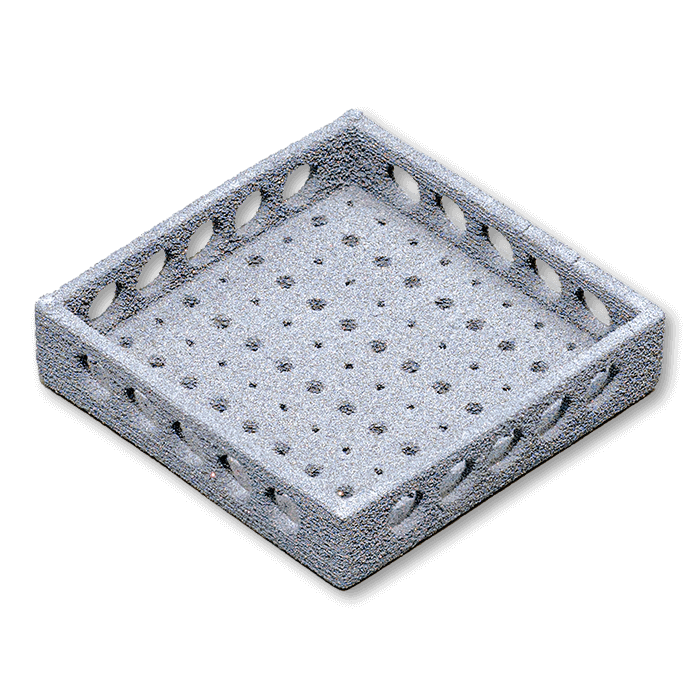

Handling & Post Processing

CONCR3DE offers all the dedicated tools to allow a fast, clean, and dust-free workflow and make light work of post processing printed parts to reach their final state after printing. These include our optional Depowdering Station, and more.

Application Optimization Service

Benefit from our years of binder jetting technology experience. Whether you are looking for a reference print, or would like us to jointly optimize product or part properties, process parameters like print speed and materials use, or scale up part dimensions or production volume altogether in the best way possible – we are here for you.