In the world of 3D printing, we often talk about concepts such as additive and subtractive manufacturing. While both methods are used to create finished products, they are radically different in their processes. But what are they exactly? And how do they relate to binder jetting?

Subtractive manufacturing

Subtractive manufacturing involves removing material from a larger block material to create the final product. This is typically done using a CNC machine that uses cutting tools to remove material until the desired shape is achieved. During this process, scrap material is created from shaping the material. Even though traditional manufacturing methods often require an expensive mold with a limited lifetime, these methods might be more cost-effective for larger production runs.

Additive manufacturing

Additive manufacturing, also known as 3D printing, is the process of building an object starting from a digital model and building the finished product layer by layer through different methods. They can include extrusion-based technologies, such as FDM, used for plastics, or techniques, such as EBM or DMLS, used for metals. In the case of binder jetting, a finished product is built by depositing a binder agent on a powder bed. The powders vary from stone to metal powders and ceramics. Additive manufacturing processes are functional when high precision is required and where there are complex geometries that traditional manufacturing methods cannot produce. Furthermore, their use is ideal for small-scale production runs or prototyping since 3D printers do not require a mold, which is often expensive. It is also great for when speed is important: the time from a CAD 3D model to a physical part can be just hours instead of weeks.

Binder jetting

Within the additive manufacturing methods, binder jetting is where our expertise lies. A differentiation between this technology and the other 3D printing methods is necessary. In binder jetting, the printhead deposits binder on a printing bed one layer at a time. This method allows for the simultaneous production of multiple parts within the same build volume, which significantly increases the throughput compared to traditional additive manufacturing techniques. Binder jetting printers usually have larger printing volume when compared to other 3D printing technologies. For example, CONCR3DE supports printing up to 6 x 3 meters in size, with a maximum height of 1 meter. Furthermore, the costs associated with printing are minimal, since the powders can be recycled with hardly any waste. All of these factors make binder jetting the most scalable 3D printing technology, enabling the user to have full production runs, but without the costs associated with molds or tooling that are often required by traditional manufacturing methods.

Which method to choose?

In summary, it depends on the specific needs of each manufacturer. Small-scale production runs of complex geometries are more suited for additive manufacturing, while subtractive manufacturing provides a smoother surface finish straight out of the mold (whereas a printed part might require post-processing to achieve the same finish), and it is more indicated for large production runs. Binder jetting is an exception, as it can be integrated in considerable production cycles, while being cost-efficient at the same time.

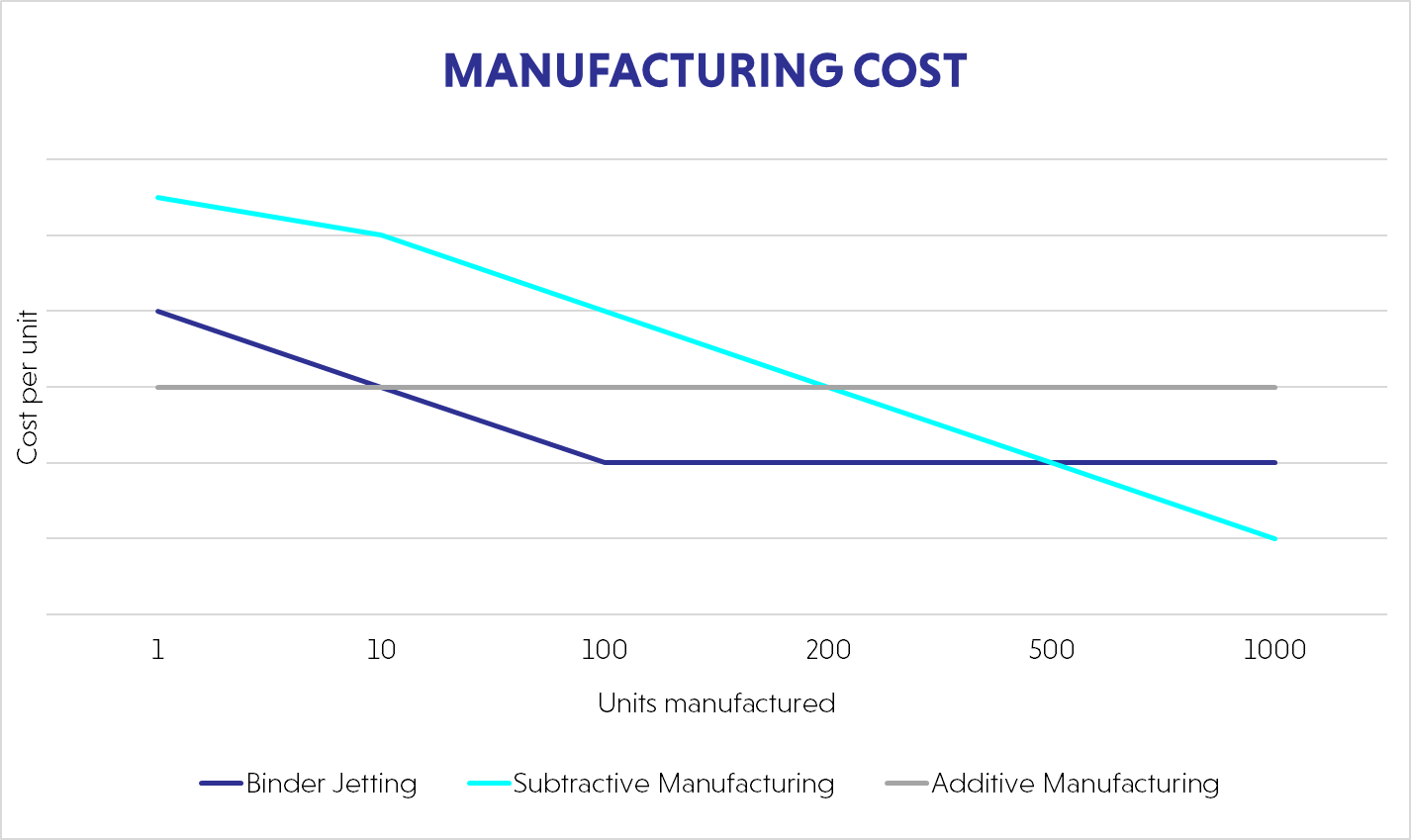

Are you considering switching to additive manufacturing processes? We advise you to take the table below as a rough reference and make the most economically-convenient decision. If additive manufacturing could be of interest, please feel free to contact us and explore the options with CONCR3DE!

If additive manufacturing could be of interest for your application, please feel free to contact us so we can help you explore the options.

Would you like to know more? Contact our team today!