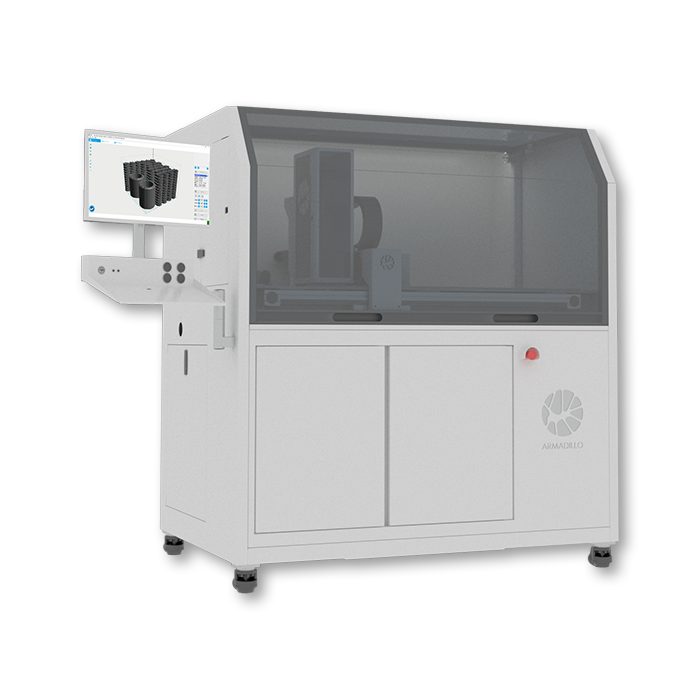

Armadillo White is a fully open R&D binder jetting printer with which researchers can develop unique, custom materials. But what does that mean exactly? What parameters are there to develop materials and what is the breadth of what is achievable?

In this article, we shine some light on which developable parameters there are and what their effect could be. But first, it is important to give a brief overview on the process itself, as well as the preparation and post processing of the result.

Binder jetting is a process in which binder (printer ink) and powder are brought together. Powder is spread in thin layers, on which binder is jetted using a print head.

This brief description already shows a range of parameters: what is the powder? What is the binder? How thin are these layers exactly? How is the powder spread? How much binder in applied? Which printhead? In which ambient conditions, such as room temperature, are these two parts brought together?

The possibilities are virtually limitless, which is why binder jetting is such versatile printing technology and why so many materials can be printed.

At CONCR3DE, we tried our best to provide a printer that allows for this incredible versatility of powders, binders, and process parameters. After all, and this is also our experience, there is nothing more frustrating than the hardware being the limitation for your material development goal.

Heat Exchanger in Copper (green state), printed on Armadillo White

Heat Exchanger in Copper (green state), printed on Armadillo White

Powder

An example of the versatility of binder jetting is found in the powder. Every powder will have different properties when it comes to particle size distribution, particle shape, packing density and weight, with each property influencing the flowability of the powder and the density of the powder in the powder bed. In turn, this effects whether or not the powder can be spread over a surface in order to form homogeneous layers for printing.

To give the researcher the best chance of spreading even layers, Armadillo White is a piston system with a counter-clockwise rotating roller. This means there is no recoater or hopper, and therefore poorly flowable powders can be spread easily. To further aid the spreading of the powder, the following parameters are adjustable:

- Y-direction movement speed

- X-direction movement speed

- Roller rotational speed

- Spreading speed

- Feed height

- Layer height

The precision of the actuators on the Z-axis have a 2µm repeatability. This means very thin layers of 40µm can be spread reliably.

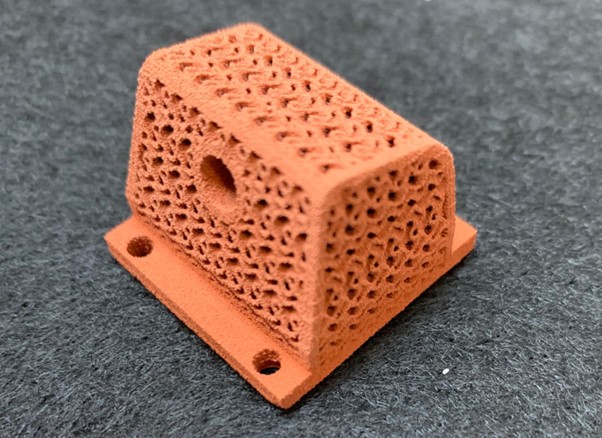

A practical example: ceramic powders, like porcelain or alumina, typically have very poor flowability because they consist of very small sub-5µm particles. At these small particle sizes, powders tend to want to stick together rather than flow freely. In a recoater or hopper, you would typically see this powder ‘bridge’, meaning it will stay in place rather than flow through holes. But in Armadillo White, you can make it flow by adjusting the spreading speed (slow is better in this case), adjusting the feed height/layer height ratio and the rotational speed of the roller. Tweaking these parameters allows you to get consistent layers spread in layer heights ranging from 60µm to 400µm.

The same goes for another hard to spread powder: cement. All mortars will consist of particles varying from 2 micron to 200 micron, with cement being very small and sand being larger. This combination of particle sizes also gives poor flowability. Something that can easily be solved by tweaking the parameters in your Armadillo.

The other side also works: foundry sand typically flows very easily due to its relatively large grain size and consistent, narrow particle size distribution. In this case the spreading is much more forgiving and the researcher can optimize the equipment to print at higher speeds than typically available.

Ceramics are typically poorly flowable powders; example printed by UWE Bristol, courtesy of David Huson

Ceramics are typically poorly flowable powders; example printed by UWE Bristol, courtesy of David Huson

Binder

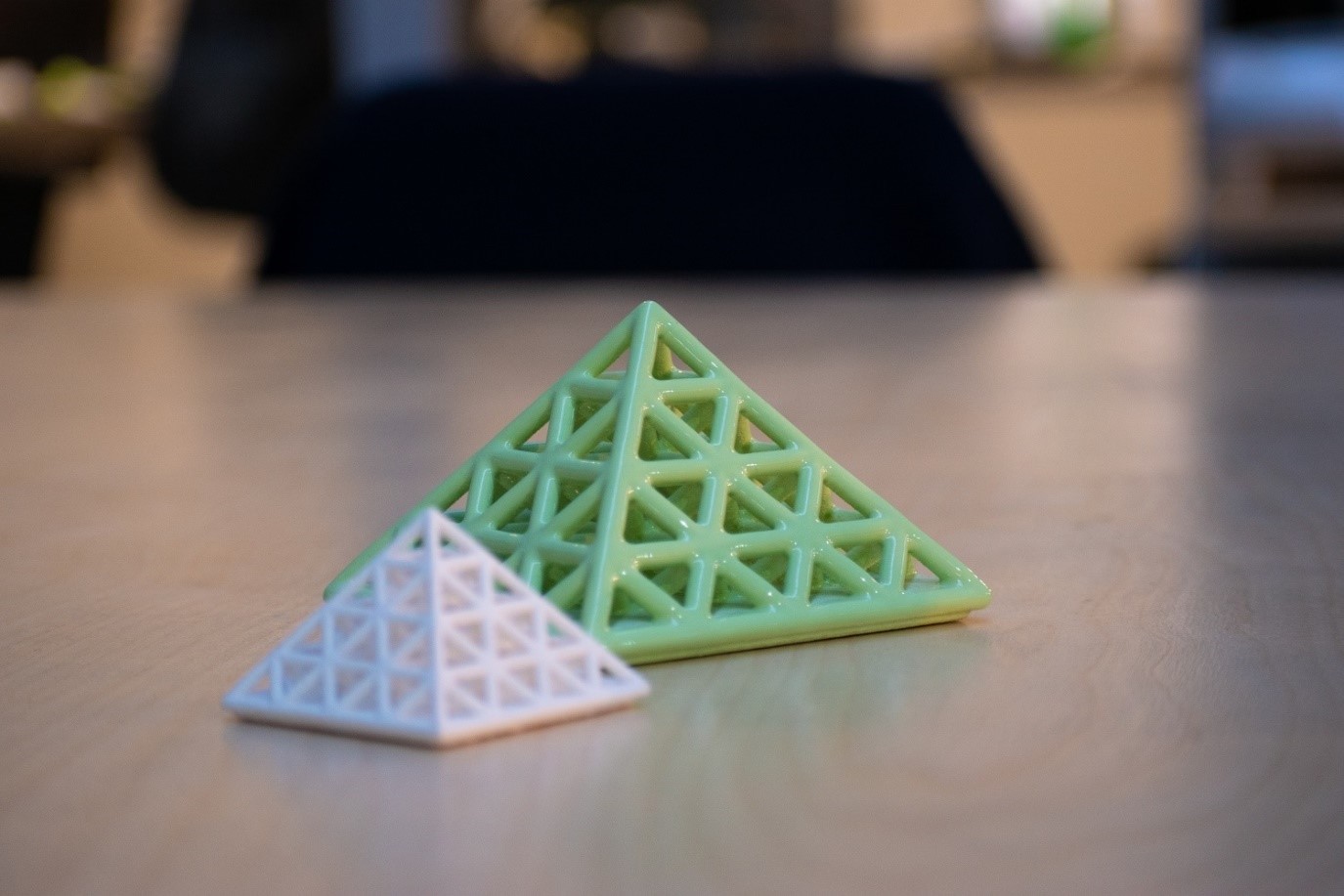

There are two keys to designing a binder for your material. The first is the chemistry: do I need a solvent, a water-based binder, a resin? Does it need particles or other additives? Does it need to have a binding agent? Is it polymeric or inorganic? The chemistry decision will depend on the material system you are trying to achieve.

The second key is the binding delivery system: the printhead. The printhead determines what rheology (a combination of viscosity, density and surface tension) is required for your binder. In Armadillo White, you can choose for a low-viscosity printhead or a high viscosity printhead. Both are highly versatile heads and can jet aqueous fluids, solvents, resins, UV-curing binders and binders containing nanoparticles.

Your choice of printhead is step 1, how the binder is ejected by the printhead is step 2. CONCR3DE gives you the freedom to adjust the waveforms that control the printhead, meaning the user can determine things like the binders’ firing frequency and droplet size. This will have an effect on the saturation level of the powder, which affects the final printed result.

That is obviously not all there is to the binder. Each liquid will behave differently and will require different flow rates and cleaning cycles. These are all adjustable in your printer. The viscosity of the binder is influenced by temperature. Both the inkjet module and the printhead are fitted with heaters, so that the researcher can heat up the binder to exactly the correct viscosity required for the process. The inkjet module is conveniently transparent, so that the researcher can visually see the flow of the binder through the inkjet module. The inkjet module is designed so that the researcher can choose to use a jerrycan for binder storage or insert binder with a 50 ml syringe, for example for very costly or volatile binders.

In Armadillo White, the researcher is free to develop unique binders. If that is not desirable, or for time reasons not feasible, CONCR3DE can also deliver a range of premade binders compatible with the printer. The range of available binders is described in this article and ranges from aqueous to solvent to phenolic to fully biodegradable.

Parts printed in Alumina 92% with particle-filled binder, courtesy of WZR Germany

Parts printed in Alumina 92% with particle-filled binder, courtesy of WZR Germany

Add-ons

Armadillo White is a modular system. This means the printer can be tuned towards the researchers’ requirements – after all, each research requires a slightly different setup. Some modules simply make research easier and some give additional functionality to the printer itself.

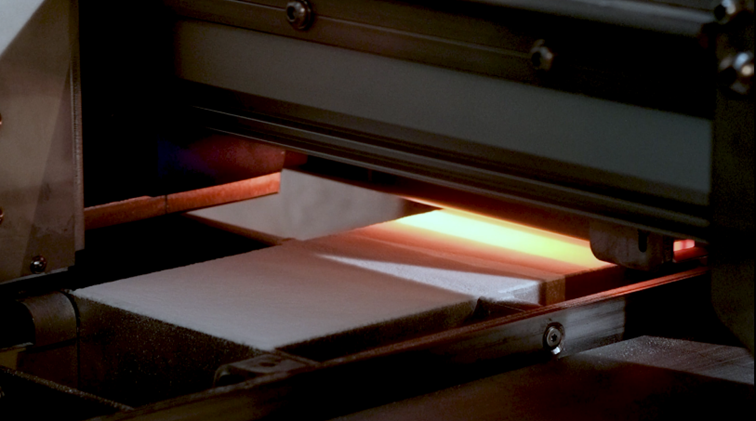

Print size Reduction Insert

This incredibly useful tool shrinks the bed size of your printer to 100 x 100 x 80 mm. This means that you can start printing parts starting with only 200 grams of powder. When you are still developing your powder, this means you are greatly reducing your mixing efforts, speeding up your research and reducing waste from batches that were not the correct mix. It is also a great solution to print high-value powders, such as specific ceramics or valuable metals.

Image 4: The Reduction Insert and Infrared Heater in action, heating up a reduced print bed

Image 4: The Reduction Insert and Infrared Heater in action, heating up a reduced print bed

Depowdering Box

Some materials, like ceramics and metals, will require curing after printing to increase their green strength. With the Depowdering Box, you can transfer the full print box directly into a drying oven, without the need to depowder them. Then, after the green strength has increased, you can safely depowder them without running the risk of breaking fragile parts.

Infrared Heater

The Infrared Heater is an add-on that can be mounted behind the roller. It consists of an infrared lamp with adjustable intensity, that can be used to heat the print bed after jetting the binder. Increased powder temperature can be useful for a variety of reasons: it can be used to lower the viscosity of the jetted binder on the powder surface for deeper penetration, it can be used to cure polymeric binding agents in the binder or powder and thereby increase the green strength of the printed parts, and in cementitious binders it can greatly shorten the curing time.

UV Curing

The UV Curing add-on can be used to create polymeric systems. It has a fixed wavelength and variable power output, which can be controlled using our NOAH software. Users can also propose a desired UV wavelength, and it is highly likely that we will be able to accommodate the request.

Using Armadillo White

We designed Armadillo White to be easy to handle and work with. The binder supply and printhead are accessible from the large front door, and there is even a side door for better access. Every printer comes with an integrated service and capping station to ensure the maximum lifetime of the printhead.

Armadillo White comes with an installation service and training, meaning once you purchase the equipment, we will plan a 2-3 day training session with you and your team, where we show you all the details of the printer and share development tips and tricks with you.

CONCR3DE CTO Matteo Baldassari training the team at a customer site in India

CONCR3DE CTO Matteo Baldassari training the team at a customer site in India

Our team has experience with a broad range of materials and applications, from foundry sand to technical ceramics to recycled sawdust to salt to concrete to many many more. The possibilities of the system are endless, and we are both eager to share our knowledge and curious to learn more about what can be done with this technology we dedicate our professional lives to.

What if it works?

Did you successfully develop a printable material? Congratulations! We’d love to keep working with you, if that’s also what you want. We have a proven track record of launching customer developed materials on our platform, where the developer can market its materials and benefit from our printers to bring it to the market. A great example is our collaboration with WZR in Germany, who used Armadillo White to successfully print Silicon Carbide. We decided together to bring their development to the market - Silicon Carbide is now part of the CONCR3DE portfolio, and available around the world.

Silicon Carbide print by WZR

Silicon Carbide print by WZR

Are you interested to develop your own materials? Would you like to try Armadillo White yourself?

Would you like to know more? Contact our team today!