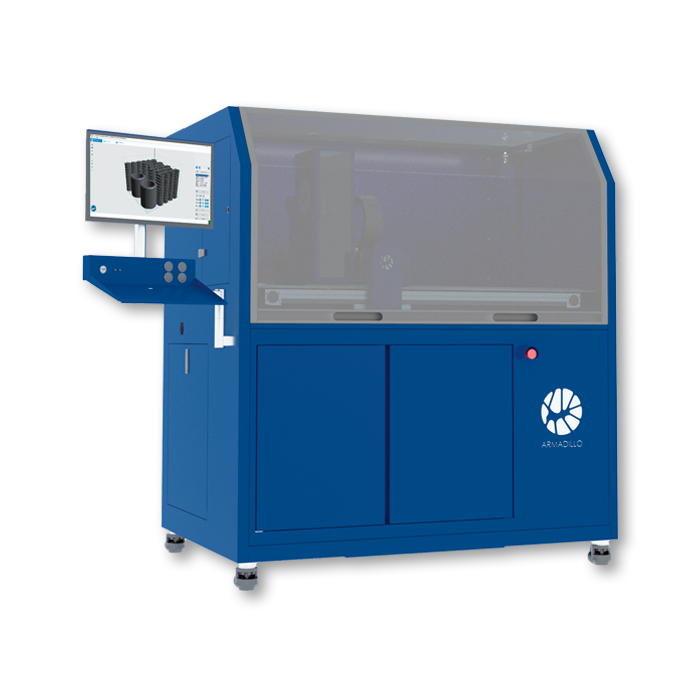

YOUR 3D POWDERHOUSE

We build powder-based 3D printers that enable the unimaginable, produce the remarkable and shape the impossible.

3D PRINTING SILICON CARBIDE (SiSiC)

We build powder-based 3D printers that enable the unimaginable, produce the remarkable and shape the impossible.

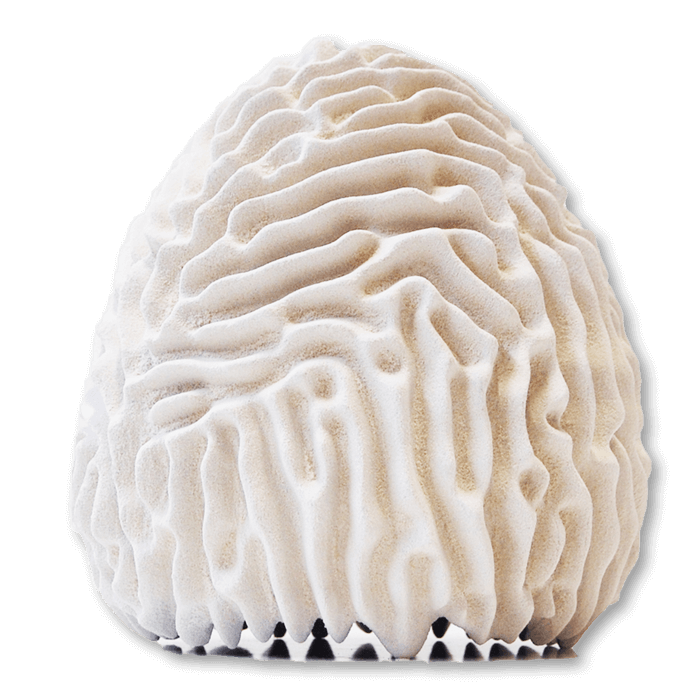

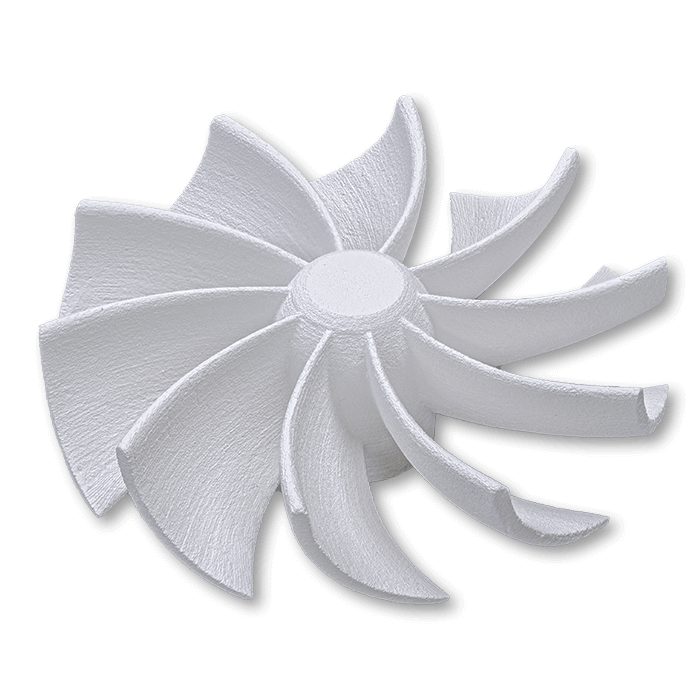

ENABLING

THE UNIMAGINABLE

Our versatile and customizable research & development product range supports your goals.

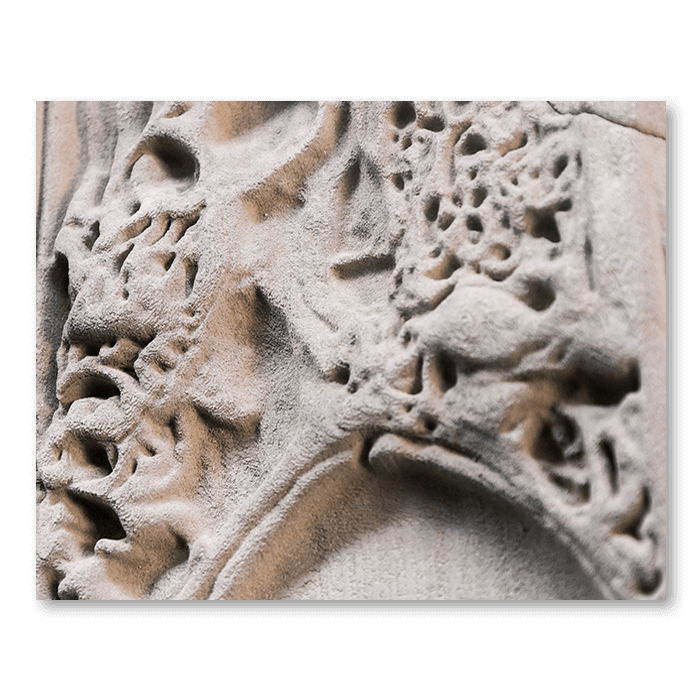

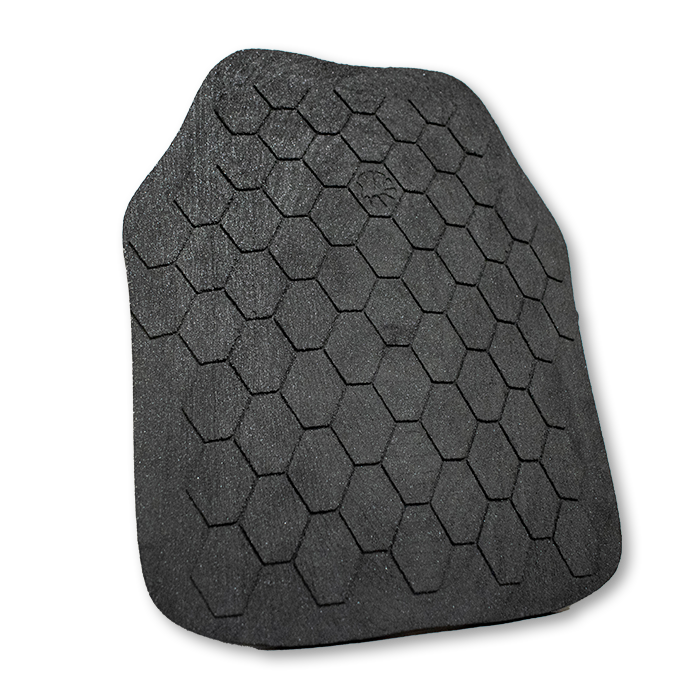

PRODUCING

THE REMARKABLE

CONCR3DE allows you to fully capitalize on the promise of additive manufacturing in industrial applications.

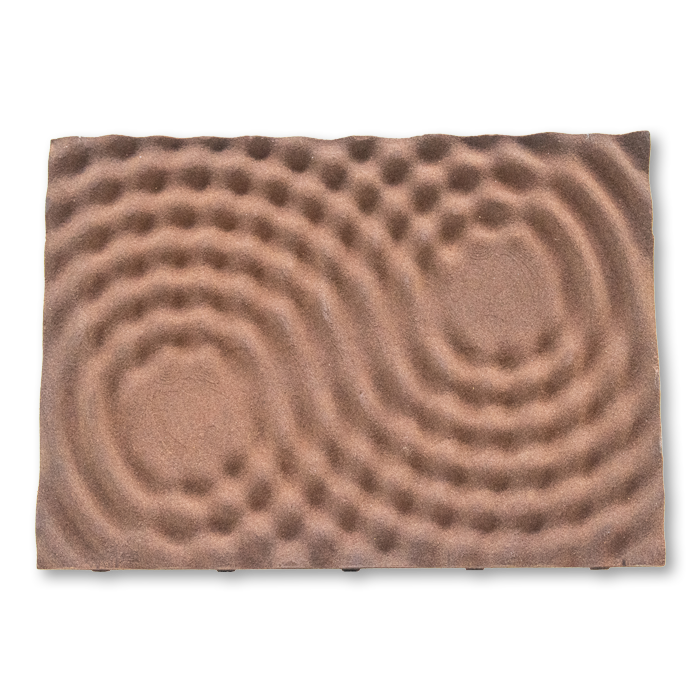

SHAPING THE IMPOSSIBLE

CONCR3DE combines additive manufacturing benefits with unprecedented scalability and novel material properties.